Production Method

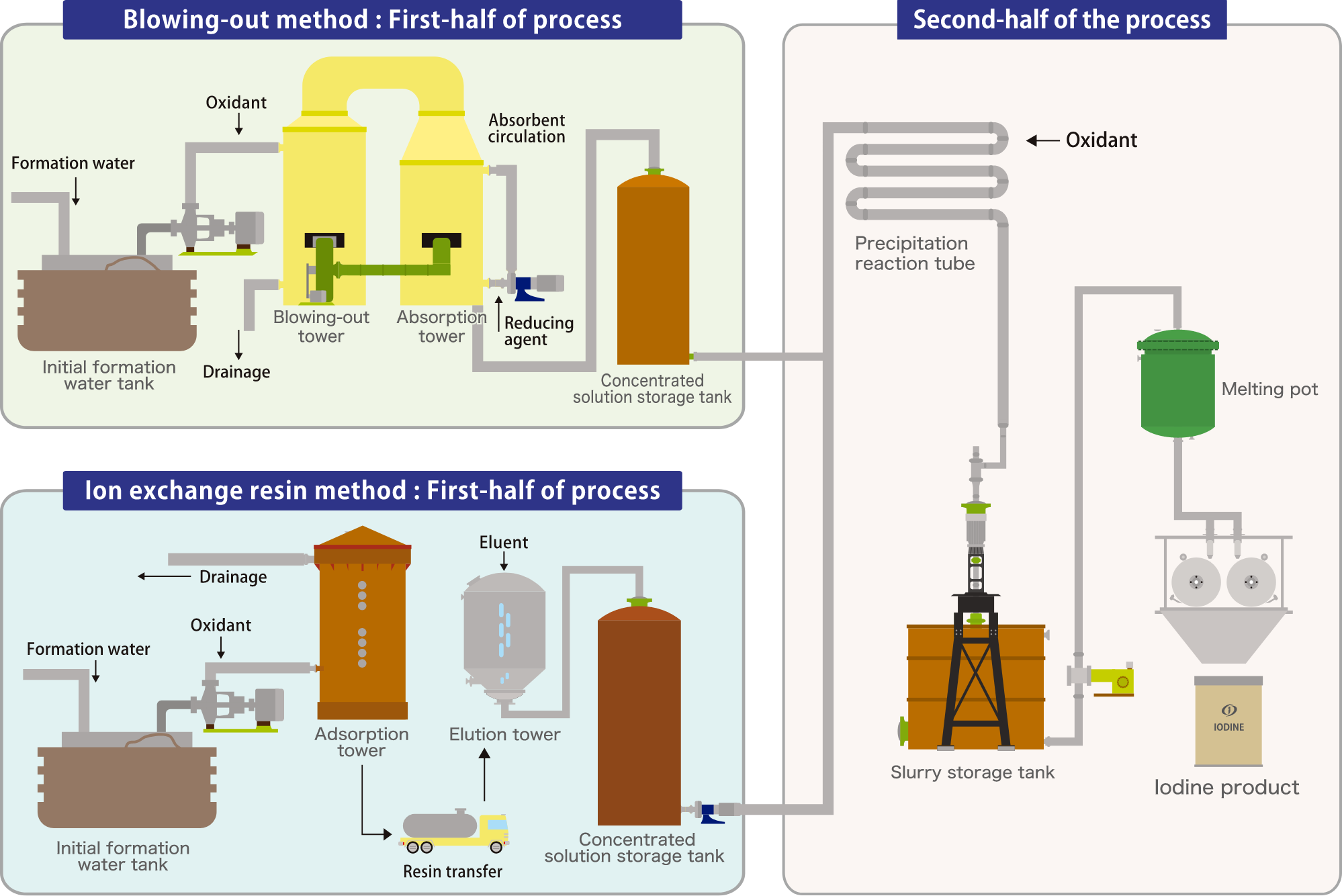

Iodine is extracted from formation water produced together with natural gas. Formation water contains about 100mg/L of iodine ions. Production of iodine consists of 2 phases. The 1st, phase of production is to produce concentrated solution by extraction and concentration. The 2nd, phase is to purify and crystalize iodine from the concentrated solution.

There are 2 methods to produce iodine. One is “Ion exchange resin method” using ion exchange resin to absorb iodine. We are the only company that has complete technology of this method. The other is “Blowing-out method” dissolving sublimated iodine into water utilizing the characteristic of iodine to easily sublimates. Ion exchange resin method is relatively small scale while Blowing-out method requires large equipment. We use both methods in combination to achieve high efficiency.

Ion Exchange Resin Method

The advantage of Ion exchange resin method is flexibility of production size and capability to process low temperature formation water. We, together with Organo Corporation, developed this technology about half a century ago.

These are the ion exchange resins.

Vergin resin (left) is light yellow and it turns black (center) after absorbing iodine ion. The resin is recycled (right) in order to minimize loss.

Blowing-out Method

This method consists of 2 processes, blowing-out process and absorption process.

The advantage of this method is simplicity. It requires only blowing-out tower while Ion exchange resin method requires more complicated equipment.

We started using this method in 2010 and have increased number of blowing-out towers to increase production.